The Magic of Microfiber - pt. I

How would you respond if a new technology promised to revolutionize most all of the tried and true processes you’ve completed countless times for years? More than likely you might harbor a healthy skepticism or playing it off as a marketing ploy. That’s a natural response, given the current age of cure all pills and endless infomercials about all-in-one miracle products. However in car care, there is one product, above all others, since its introduction over a decade ago, has completely reshaped the landscape of almost every process for all detailers, from professionals to weekend warriors alike. Nothing escaped its influence from paint correction to interior cleaning to how enthusiasts baby their vehicles has been transformed by the magical cloth that is Microfiber.

This first installment regarding microfiber will cover the basics of the technology and composition of the material in regards to its most popular uses in the automotive car care industry.

The history of Microfiber technology has a few varying stories of origins in the late 1980’s/ early 90’s (with development even dating back up to 100years prior), however what is for certain, is that Microfiber [in the auto industry] is a synthetic fiber composed of a blend of Polyester and Polyamide. These fibers are 1/100th the diameter of a human hair and 1/20th the diameter of a single strand of silk. This allows them to be extremely soft while adding much more surface area for trapping dirt or debris when cleaning. In addition, since these weaves are loosely constructed, millions of spaces exist within the fibers to allow for the trapping of particles during use. These are the two revolutionary aspects of Microfiber that grant it its 'Magical Properties.'

Construction: Polyester is, by far, the most abundant and inexpensive of the two materials used. This fiber lends to the towels overall strength under use and durability over time. Polyamide grants microfiber its absorbency characteristics and is the more costly fiber to manufacture. Most basic towels found on the market are a 80/20 blend of Polyester to Polyamide. While these are good at all around cleaning, they do not maximize a Microfiber towel’s true absorbency potential. A towel constructed of 70/30 is one that is capable of absorbing 7 or more times its weight in liquid.Also, note that those towels that are of a 70/30 construction tend to be of a higher craftsmanship.

GSM: [grams per square meter] is a measure of the density of how many fibers are in a given weave composition. GSM is a highly touted statistic in the car care industry because many believe GSM to be the overall governing factor for determining Microfiber quality. This is not the case at all, however that doesn’t slow the myth from being perpetuated. For car care purposes the minimum GSM for maintaining paint without scratching is 300-350 GSM. Although many individuals will claim blasphemy for using anything under 500 GSM on paint that is simply not the case. GSM must be combined with other characteristics of a towel to gauge its overall quality. More on that later.

Pile: the term used to describe each visible strand of a microfiber cloth. Each pile is constructed of thousands upon thousands of individual microfiber strands. There are Four GENERAL pile types: ultra-low[no pile] pile, low pile, medium pile and high pile.There are variations on these, however for clarity’s sake these are the main types widely sold in the market. Generally, the longer the pile the softer the towel will feel. This is not always the case, but it is partial truth because there are more piles that are touching and conforming to your hand on the ‘softness factor’ test. More on the pile types below.

Ultra low [no pile] are the cloths you receive when you buy new glasses or sunglasses. They are suited for trapping and removing human oils and tiny particles without smearing. These are almost utterly useless for any other sorts of tasks.

Targeted uses: Glass cleaning, navigation/electronics console cleaning.

Low pile is best suited for the removal of compounds, polishes, and waxes. Since the pile is short is has no flex in regards to the surface it’s in contact with, therefore it cannot shift and is forced into action to pick up whatever is being removed. That is why it is considered ‘grabby’ and is the best sort of ‘scrubbing’ microfiber pile.

Targeted uses: Removal of compounds, polishes, waxes. Stubborn spot removal on hard surfaces

Medium pile [combination low/med pile shown.. medium pile on back side pictured near arrow above] is the versatile tool in the microfiber toolbox. While it can remove wax [no as well as a low pile] to an adequate level, it is great for general cleaning and is the beginning level of absorbency. You could theoretically use a towel with a lower pile to soak up liquid, however it would fail to meet expectations miserably.Often medium pile MF cloths are manufactured with a low pile side and a medium pile side, allowing for versatility of usage.

Targeted uses: general cleaning, interior cleaning

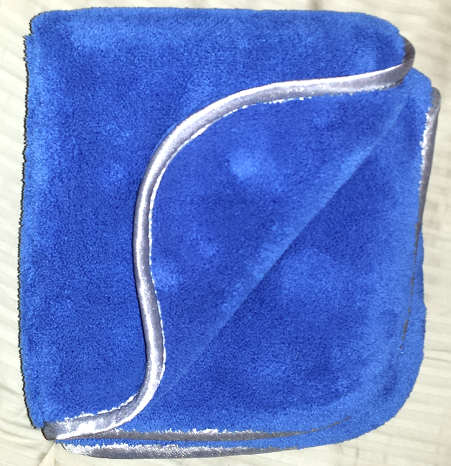

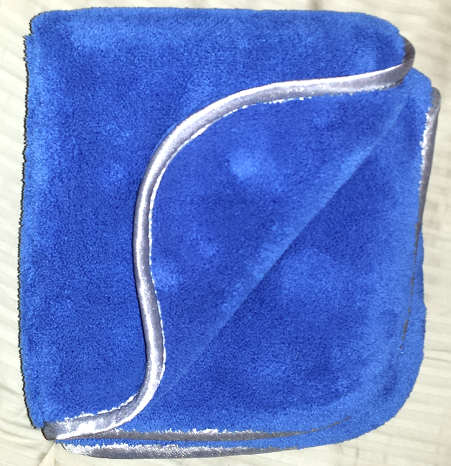

High pile is best for ultra-absorbency and trapping the most debris. Both of these are due to the fact that a longer pile allows for more surface area of the cloth.

[ pictured above: (dark blue - typical high dense pile) (light blue - extra high shaggy pile)

Targeted uses: drying, waterless washing, quick detailer.

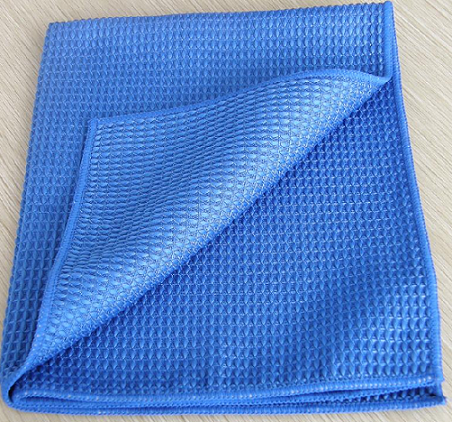

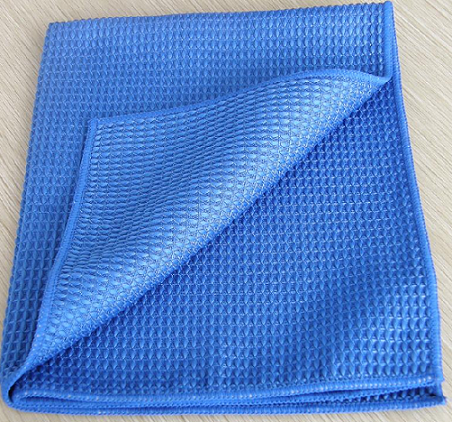

Waffle weave: while this is not per-say a pile type, it is a commonly used, debated, and discussed weave type. The name alludes to the weave’s shape, which is similar to Belgian waffles. This low profile “pile” is utilized mostly for its cleaning [particularly glass] and absorbency properties.

The main attributes for choosing a microfiber towel for your intended purpose involve balancing: towel size, [The most common sizes are 16”x16” and 16”x24”], construction ratio, GSM, and pile height. Size is relevant because it conforms to intended usage. Commonly a larger towel is preferred for drying for ease of use, whereas a smaller towel would be preferred for interior window cleaning.

Another note for Microfiber purchasing is the lint factor. Different pile and quality types have different levels of linting: the amount of lint they leave behind when used on a surface. Obviously when removing a polish or doing a final IPA wipe down no lint is desired. However for other tasks, such as miscellaneous cleaning of door jambs, wheels, interior scrubbing, etc. lint would not prove as much a point of emphasis.

While there are other attributes of Microfiber makeup that could be discussed here such as; fiber edge construction, towel border edging, and origin of production, this first installment about Microfiber is meant as a general overview for the everyman, not as the definitive article.

Stay tuned for Pt. II:

How would you respond if a new technology promised to revolutionize most all of the tried and true processes you’ve completed countless times for years? More than likely you might harbor a healthy skepticism or playing it off as a marketing ploy. That’s a natural response, given the current age of cure all pills and endless infomercials about all-in-one miracle products. However in car care, there is one product, above all others, since its introduction over a decade ago, has completely reshaped the landscape of almost every process for all detailers, from professionals to weekend warriors alike. Nothing escaped its influence from paint correction to interior cleaning to how enthusiasts baby their vehicles has been transformed by the magical cloth that is Microfiber.

This first installment regarding microfiber will cover the basics of the technology and composition of the material in regards to its most popular uses in the automotive car care industry.

The history of Microfiber technology has a few varying stories of origins in the late 1980’s/ early 90’s (with development even dating back up to 100years prior), however what is for certain, is that Microfiber [in the auto industry] is a synthetic fiber composed of a blend of Polyester and Polyamide. These fibers are 1/100th the diameter of a human hair and 1/20th the diameter of a single strand of silk. This allows them to be extremely soft while adding much more surface area for trapping dirt or debris when cleaning. In addition, since these weaves are loosely constructed, millions of spaces exist within the fibers to allow for the trapping of particles during use. These are the two revolutionary aspects of Microfiber that grant it its 'Magical Properties.'

Construction: Polyester is, by far, the most abundant and inexpensive of the two materials used. This fiber lends to the towels overall strength under use and durability over time. Polyamide grants microfiber its absorbency characteristics and is the more costly fiber to manufacture. Most basic towels found on the market are a 80/20 blend of Polyester to Polyamide. While these are good at all around cleaning, they do not maximize a Microfiber towel’s true absorbency potential. A towel constructed of 70/30 is one that is capable of absorbing 7 or more times its weight in liquid.Also, note that those towels that are of a 70/30 construction tend to be of a higher craftsmanship.

GSM: [grams per square meter] is a measure of the density of how many fibers are in a given weave composition. GSM is a highly touted statistic in the car care industry because many believe GSM to be the overall governing factor for determining Microfiber quality. This is not the case at all, however that doesn’t slow the myth from being perpetuated. For car care purposes the minimum GSM for maintaining paint without scratching is 300-350 GSM. Although many individuals will claim blasphemy for using anything under 500 GSM on paint that is simply not the case. GSM must be combined with other characteristics of a towel to gauge its overall quality. More on that later.

Pile: the term used to describe each visible strand of a microfiber cloth. Each pile is constructed of thousands upon thousands of individual microfiber strands. There are Four GENERAL pile types: ultra-low[no pile] pile, low pile, medium pile and high pile.There are variations on these, however for clarity’s sake these are the main types widely sold in the market. Generally, the longer the pile the softer the towel will feel. This is not always the case, but it is partial truth because there are more piles that are touching and conforming to your hand on the ‘softness factor’ test. More on the pile types below.

Ultra low [no pile] are the cloths you receive when you buy new glasses or sunglasses. They are suited for trapping and removing human oils and tiny particles without smearing. These are almost utterly useless for any other sorts of tasks.

Targeted uses: Glass cleaning, navigation/electronics console cleaning.

Low pile is best suited for the removal of compounds, polishes, and waxes. Since the pile is short is has no flex in regards to the surface it’s in contact with, therefore it cannot shift and is forced into action to pick up whatever is being removed. That is why it is considered ‘grabby’ and is the best sort of ‘scrubbing’ microfiber pile.

Targeted uses: Removal of compounds, polishes, waxes. Stubborn spot removal on hard surfaces

Medium pile [combination low/med pile shown.. medium pile on back side pictured near arrow above] is the versatile tool in the microfiber toolbox. While it can remove wax [no as well as a low pile] to an adequate level, it is great for general cleaning and is the beginning level of absorbency. You could theoretically use a towel with a lower pile to soak up liquid, however it would fail to meet expectations miserably.Often medium pile MF cloths are manufactured with a low pile side and a medium pile side, allowing for versatility of usage.

Targeted uses: general cleaning, interior cleaning

High pile is best for ultra-absorbency and trapping the most debris. Both of these are due to the fact that a longer pile allows for more surface area of the cloth.

[ pictured above: (dark blue - typical high dense pile) (light blue - extra high shaggy pile)

Targeted uses: drying, waterless washing, quick detailer.

Waffle weave: while this is not per-say a pile type, it is a commonly used, debated, and discussed weave type. The name alludes to the weave’s shape, which is similar to Belgian waffles. This low profile “pile” is utilized mostly for its cleaning [particularly glass] and absorbency properties.

The main attributes for choosing a microfiber towel for your intended purpose involve balancing: towel size, [The most common sizes are 16”x16” and 16”x24”], construction ratio, GSM, and pile height. Size is relevant because it conforms to intended usage. Commonly a larger towel is preferred for drying for ease of use, whereas a smaller towel would be preferred for interior window cleaning.

Another note for Microfiber purchasing is the lint factor. Different pile and quality types have different levels of linting: the amount of lint they leave behind when used on a surface. Obviously when removing a polish or doing a final IPA wipe down no lint is desired. However for other tasks, such as miscellaneous cleaning of door jambs, wheels, interior scrubbing, etc. lint would not prove as much a point of emphasis.

While there are other attributes of Microfiber makeup that could be discussed here such as; fiber edge construction, towel border edging, and origin of production, this first installment about Microfiber is meant as a general overview for the everyman, not as the definitive article.

Stay tuned for Pt. II:

, and is so open and willing to share it.

, and is so open and willing to share it.

Comment