This is my idea, can it work?

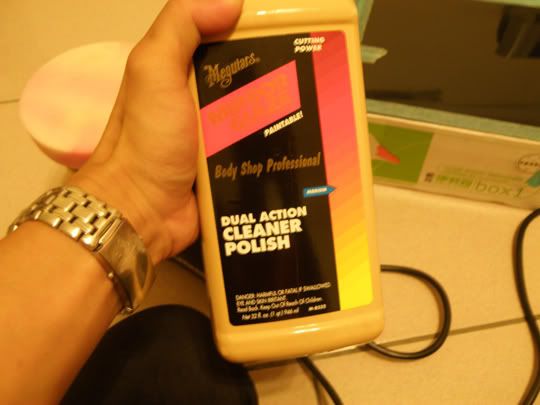

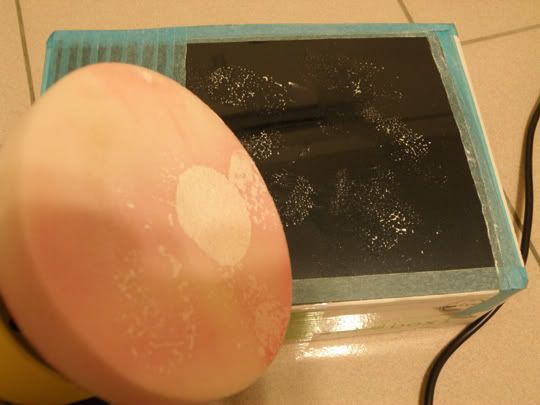

I don't want to buy one more machine for cutting...

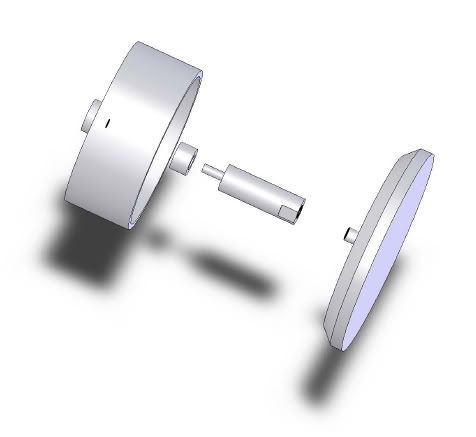

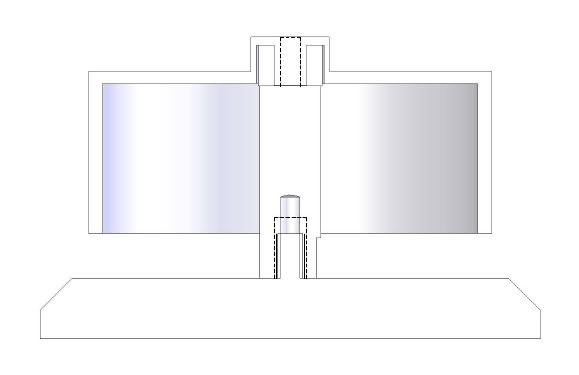

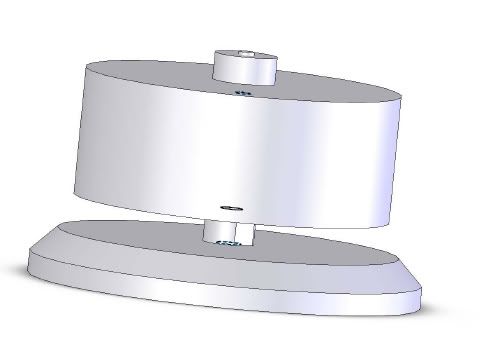

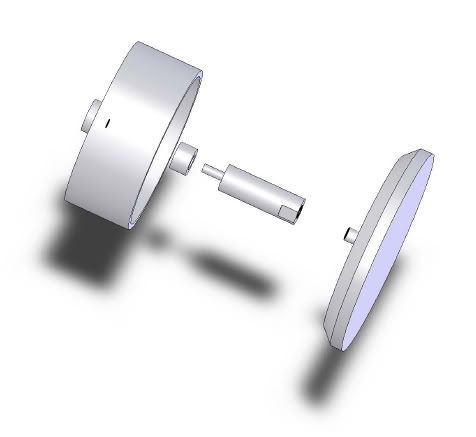

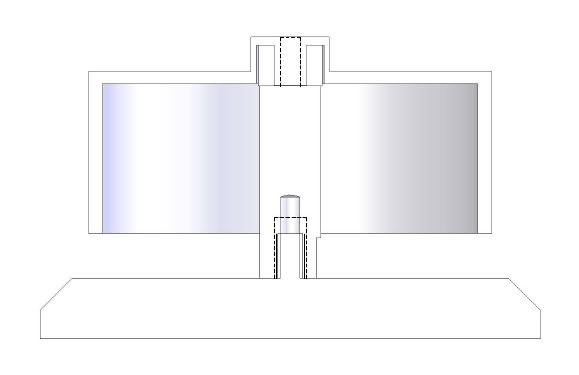

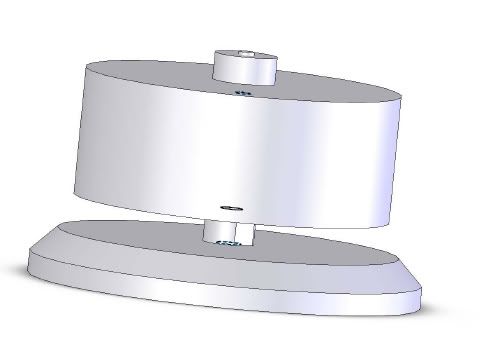

Just want to make an adapter, let G110 had two function...

I don't want to buy one more machine for cutting...

Just want to make an adapter, let G110 had two function...

)

)

Comment