From a couple of weekend's ago, this is Stuhil's lovely Audi A4 S-Line. Booked in for a tuition detail so Stuart could learn the techniques being used on the detail as well as getting the car detailed, and the end results are therefore part of Stuart's own hard work as well as ours - very rewarding for both us, and for anyone wanting to achieve the results themselves  Davy, Gordon and myself on the team today

Davy, Gordon and myself on the team today

As mentioned in a previous thread, as a team we are looking at pushing forward and expanding our washing techniques to suit different situations where we may be working - from unit where we can use snowfoam and water happily, to showgrounds where washing is restricted with no hose, to inside garages where classic cars cannot be easily moved outside for washing. On this detail, we chose to wash the car inside using Optimum No Rinse shampoo for the bodywork and the steam cleaner for wheels and arches.

ONR for me has major advantages for those wanting to wash their car and make sure its perfect at a show... its not always possible to get a rinsing hose, but getting a bucket of water is much easier. Careful wash technique is required but over the past weeks and months we have been developping this and seeing what works best to ensure safe washing. The car, ready for washing indoors:

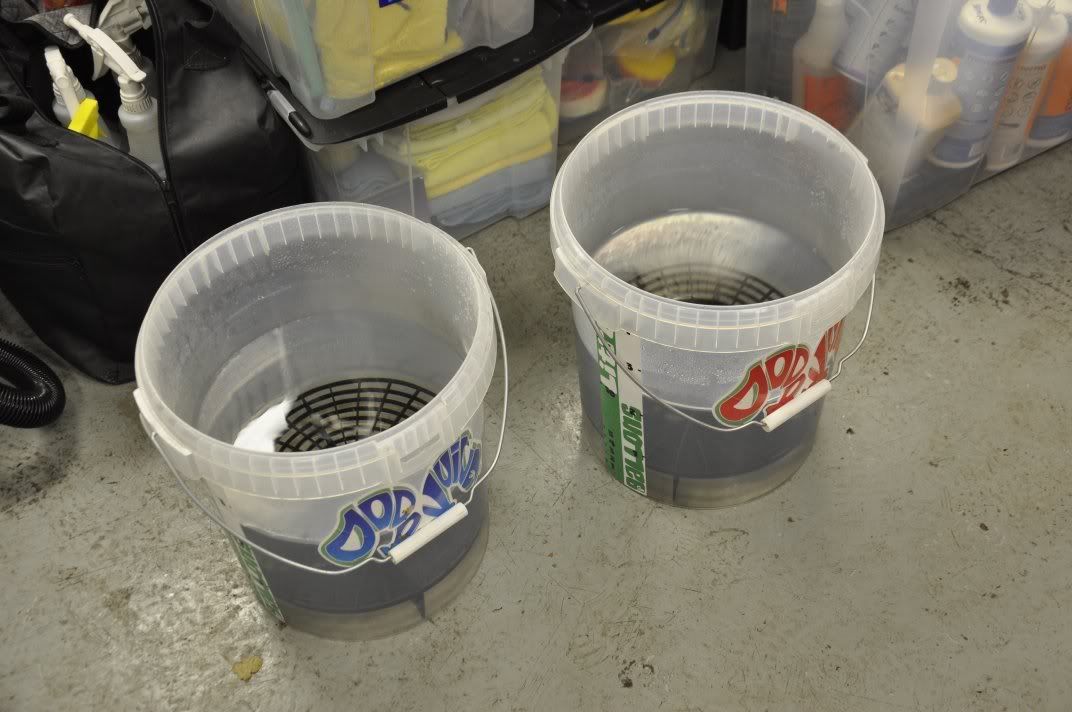

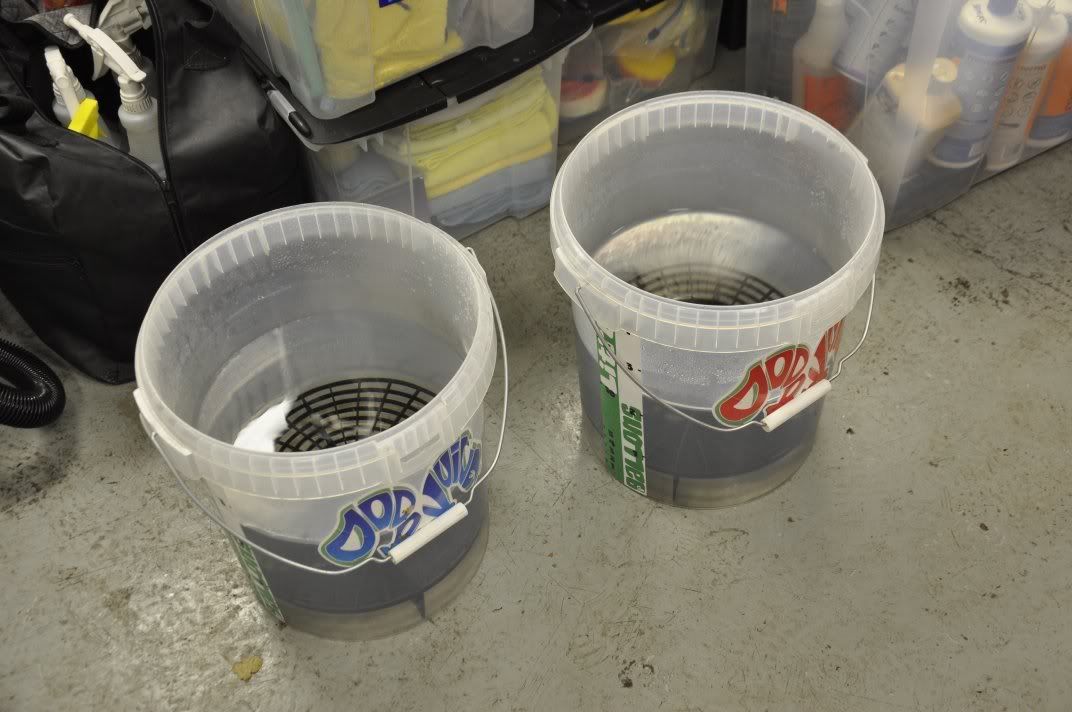

As a traditional wash, two buckets prepared with water:

In one bucket, Gordon here adds a couple of capfuls of ONR to the wash bucket...

The philosophy behind ONR is a super slick wash solution which encapsulates dirt so it slides off of the paintwork without marring. This does seem to work, as we have been using Gordon's Vectra as a test mule for this since the summer months But it does require the correct method to be used, adapt a little from traditiona two bucket wash! The key is not to have shed loads of water on the car, all running pff everywhere - squeeze a lot of the water out of the sponge (do not use a mitt):

But it does require the correct method to be used, adapt a little from traditiona two bucket wash! The key is not to have shed loads of water on the car, all running pff everywhere - squeeze a lot of the water out of the sponge (do not use a mitt):

Then gently with no pressure wipe the sponge over the region of paint. Only go small distances, espeically on dirty panels and return to rinse bucket often to clean sponge and then renew with ONR solution from wash bucket. Some common sense is required here - if the panel is very dirty, go only a very small distance and return to bucket often. Dont press down, keep returning to same area with more passes instead if more cleaning is needed. The sponge should be lightly swept acorss the paint...

The water from the solution then sheets and runs off...

Lightly dry the panel following with a drying towel - as the name suggests, no rinsing is required. This minimises water used, and also minimised water spilling everywhere which when inside or at a showground is highly desireable!

The wheel were cleaned using the Steam Cleaner... as you can see, pretty clean anyway in the befores:

Because they were in good condition, the wheels could be cleaned with no chemicals with the steam cleaner... a little Bilberry, or APC could be added to the cleaning brush. To ensure you dont mark the alloy, as you do with paint, only use very light pressure with the brush and go over areas often rather than trying to shift everything in one go. The wheel insides with the steam cleaner...

You can see the dirt being removed with the method...

Working away on the faces of the wheel...

and on the arches...

The end results...

We'd say they were pretty clean Now, any severe pitting or tar for example would require a tar remover but be aware that old clay can also be used if for some reason aggressive chemicals cannot be used for removing tar... takes longer, and does ruin the clay but the option is there. The key is to be flexible, widen your armoury of techniques to deal with a variety of situations you may be faced with as the more time I spend detailing, the more I see that traditional methods are not always readily applicable and the ability to change and adapt is very important.

Now, any severe pitting or tar for example would require a tar remover but be aware that old clay can also be used if for some reason aggressive chemicals cannot be used for removing tar... takes longer, and does ruin the clay but the option is there. The key is to be flexible, widen your armoury of techniques to deal with a variety of situations you may be faced with as the more time I spend detailing, the more I see that traditional methods are not always readily applicable and the ability to change and adapt is very important.

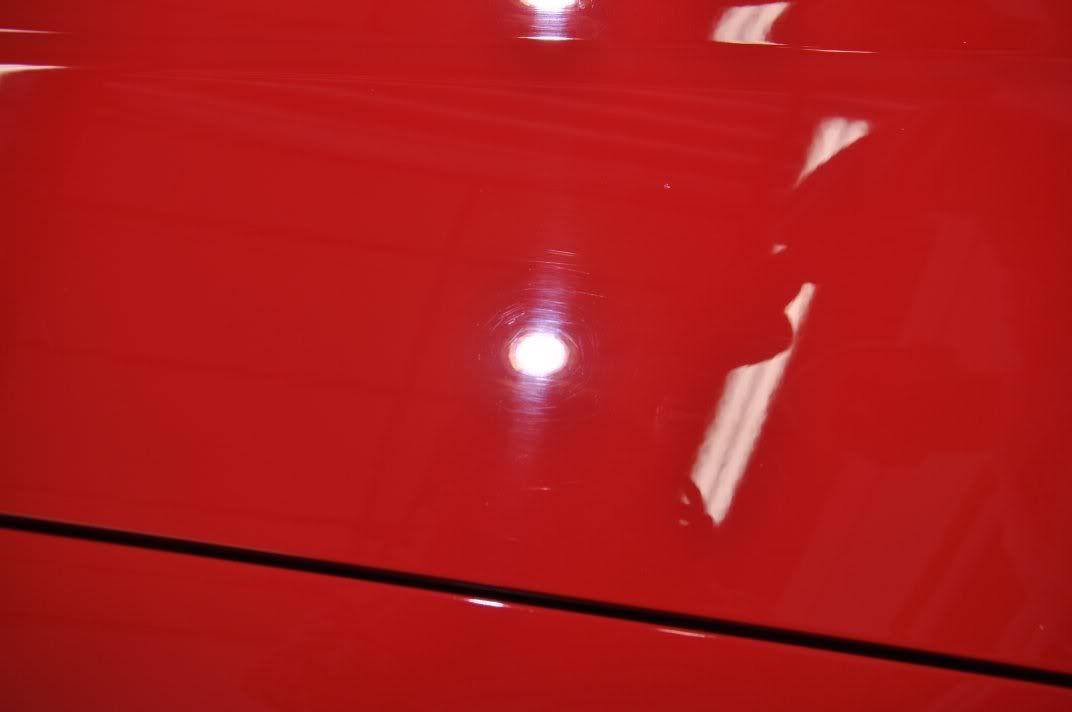

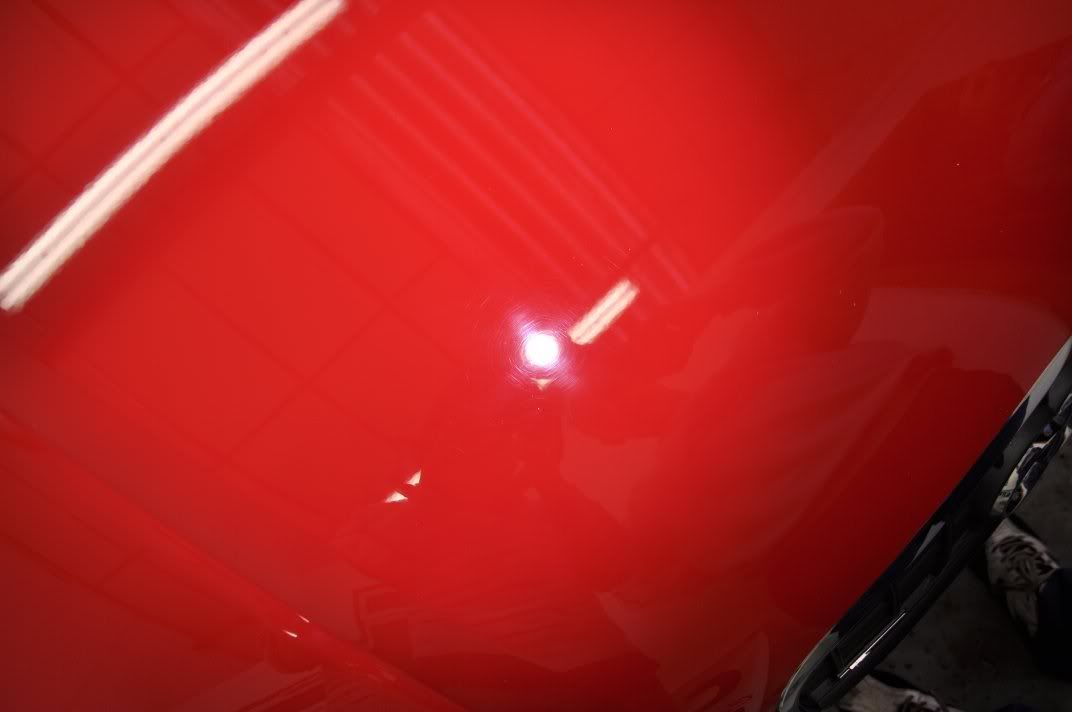

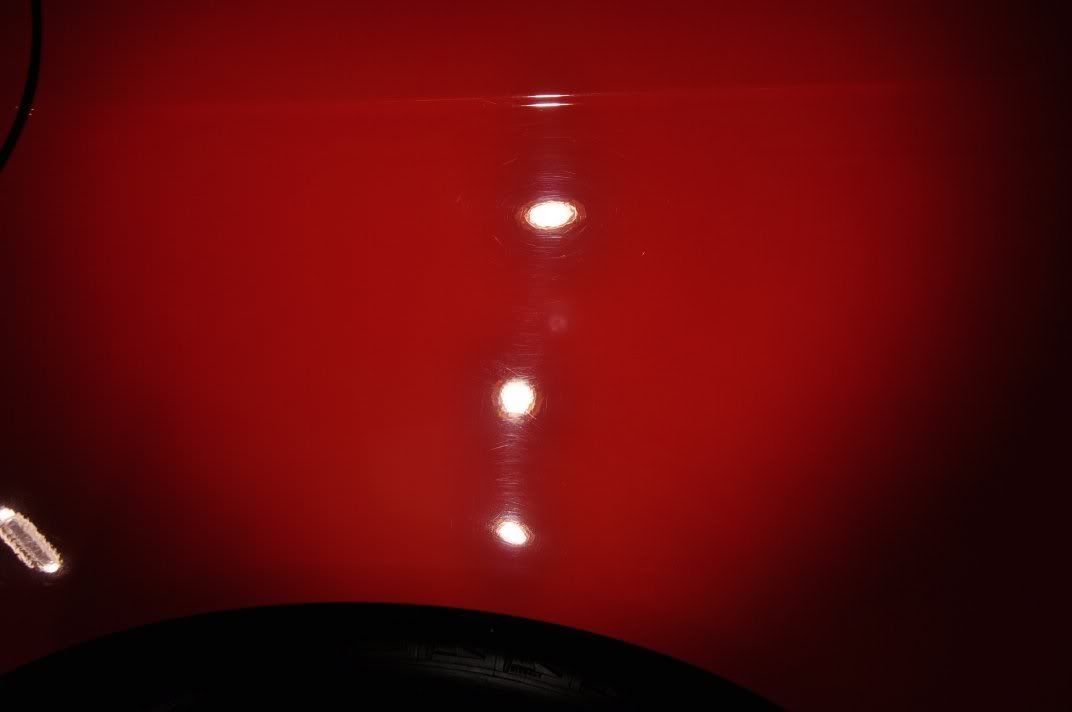

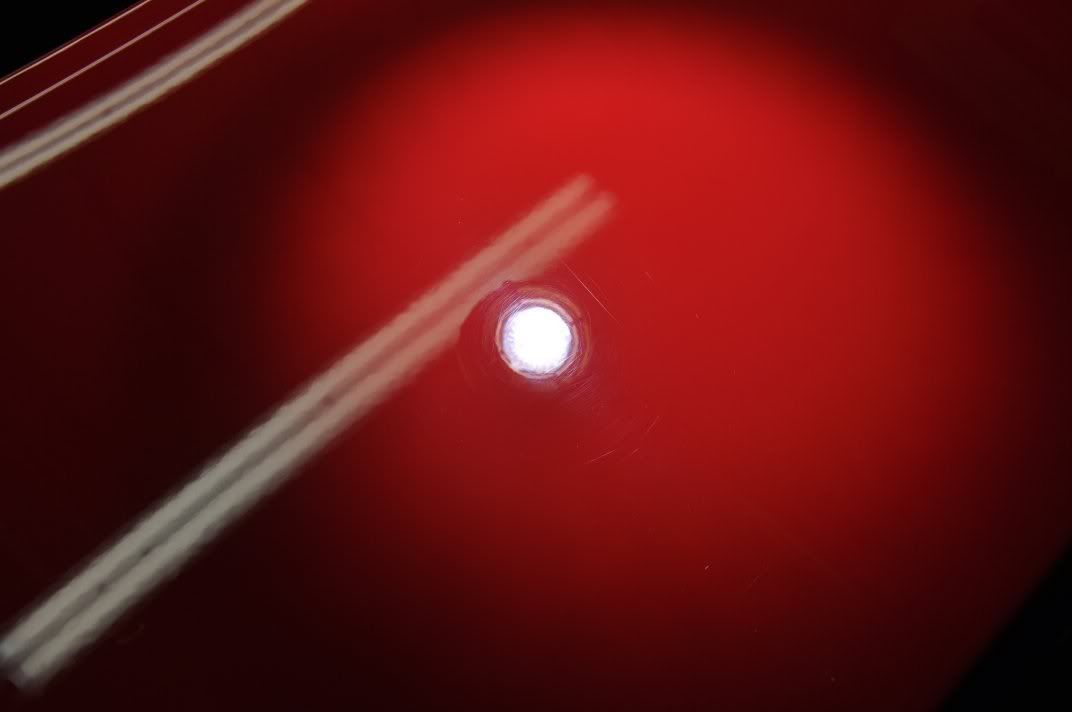

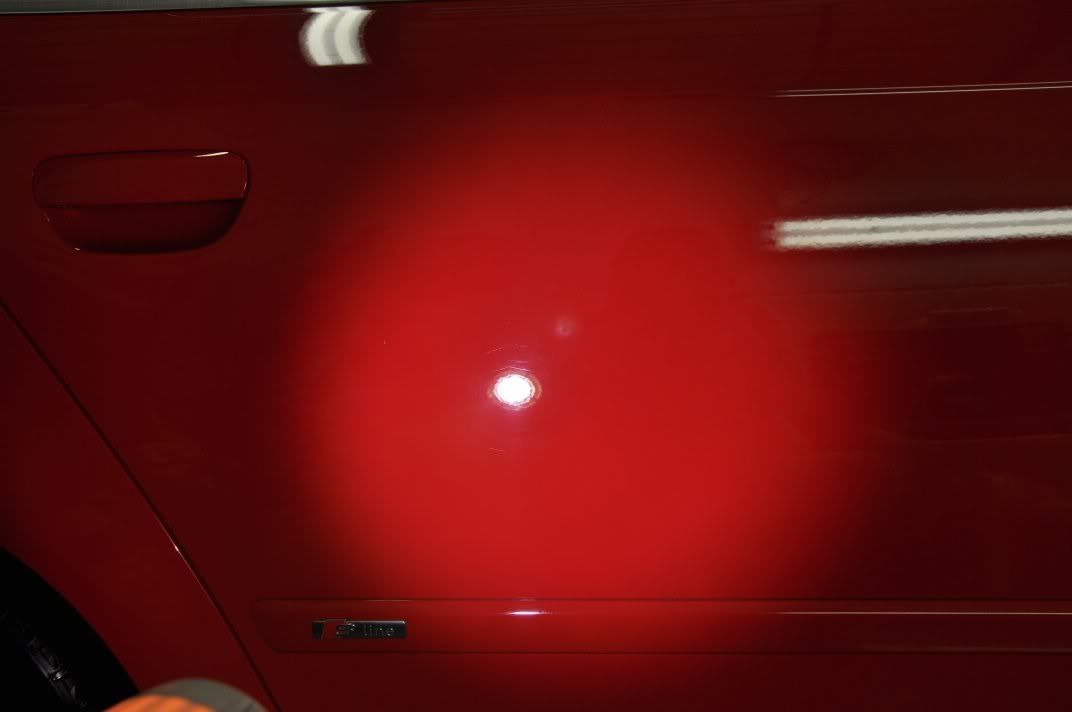

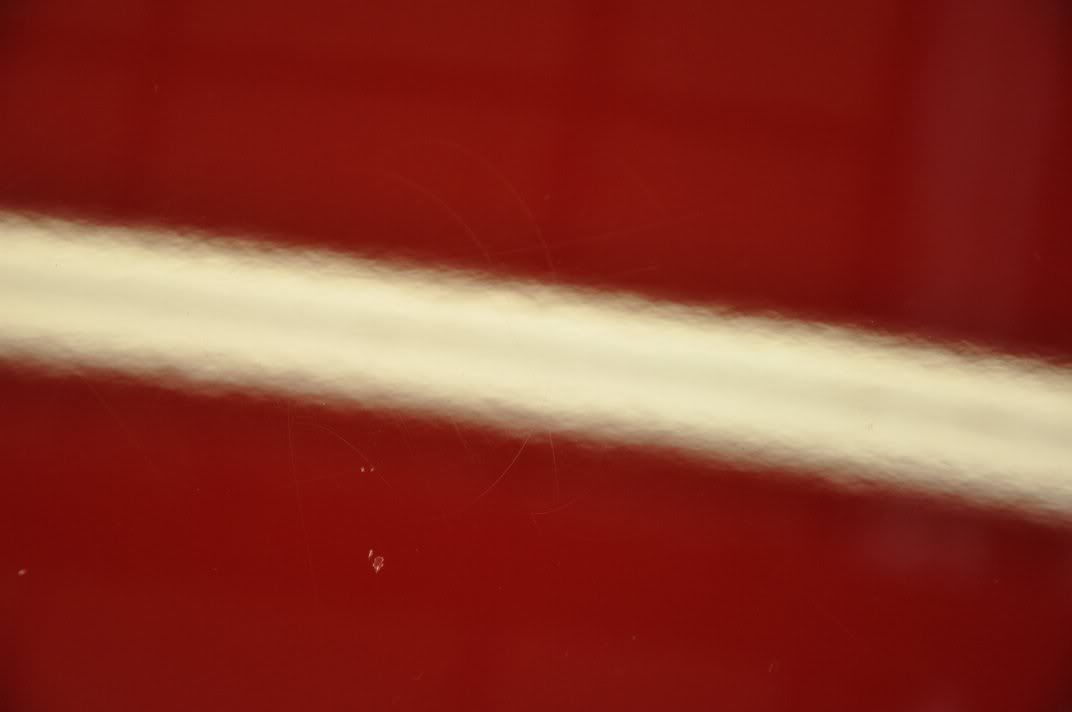

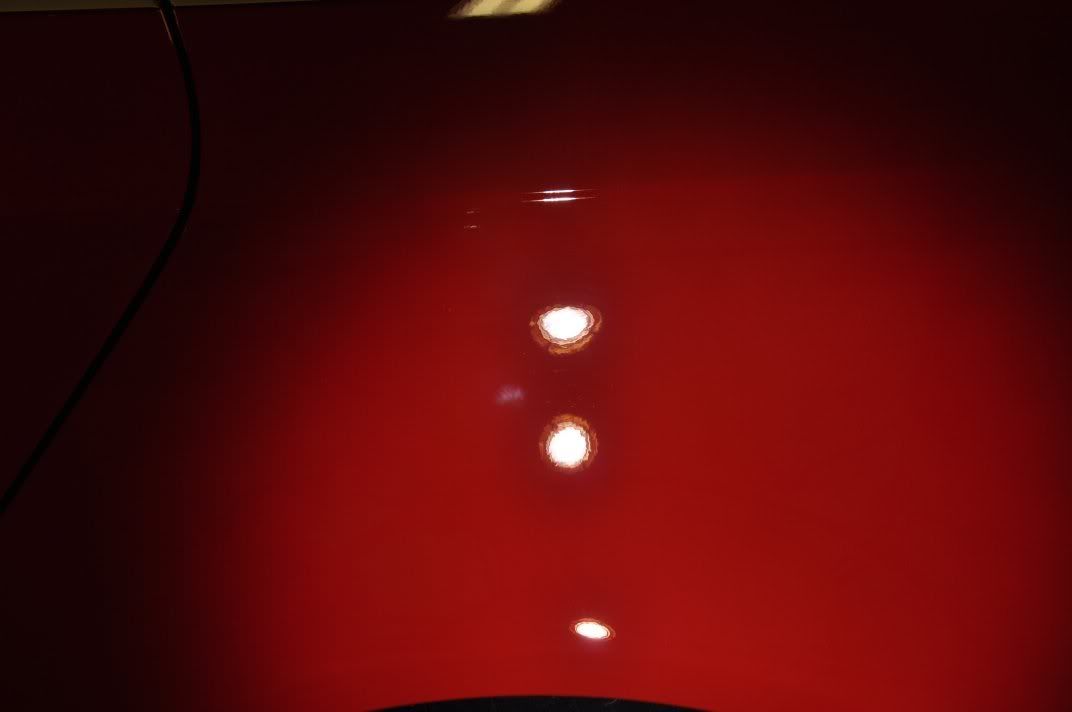

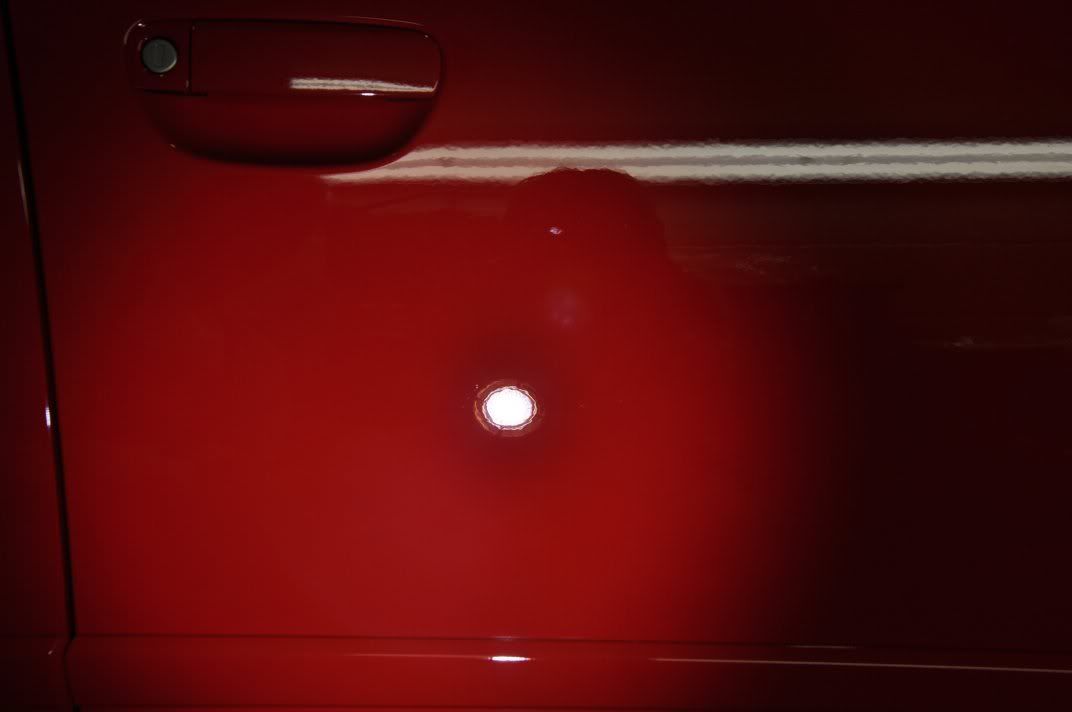

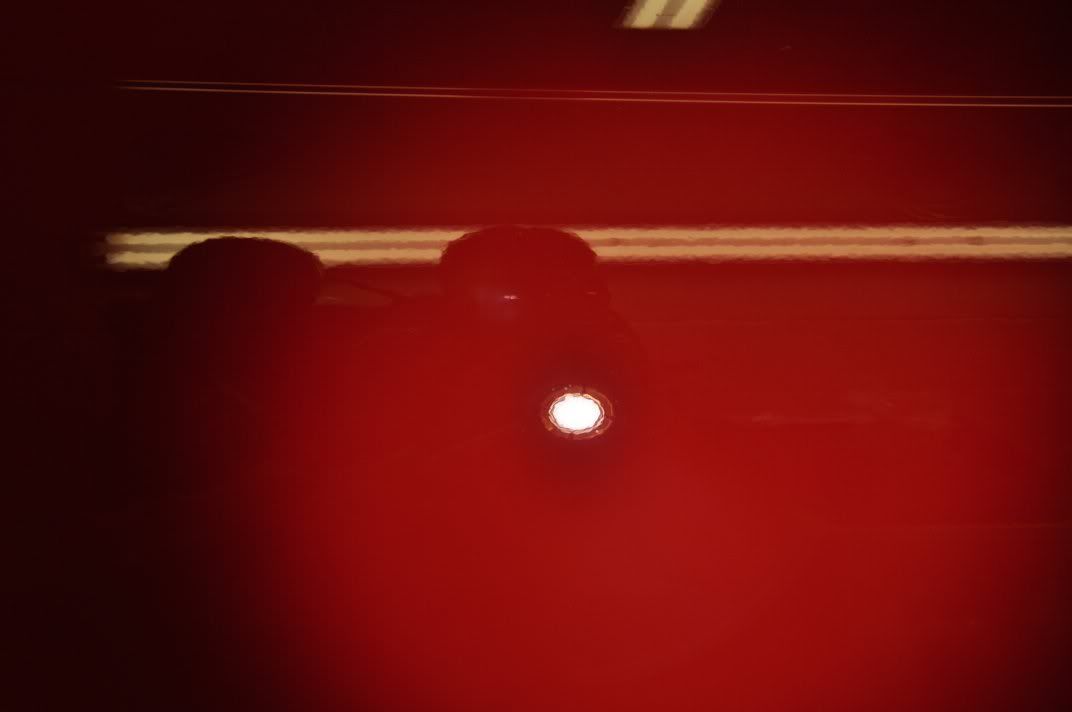

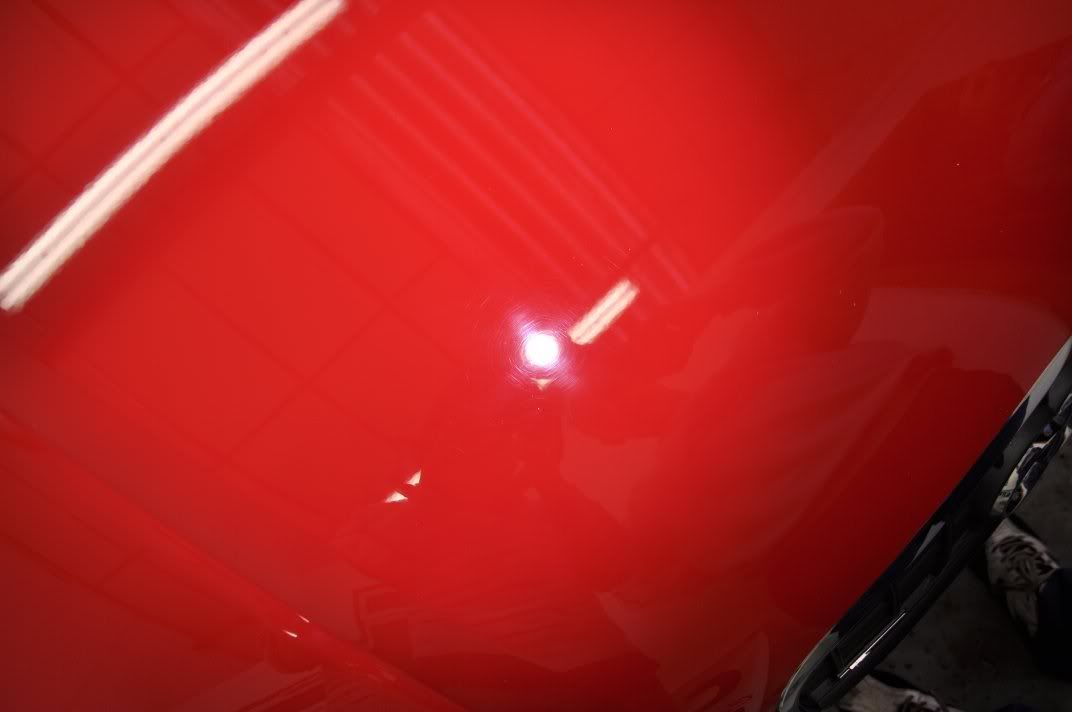

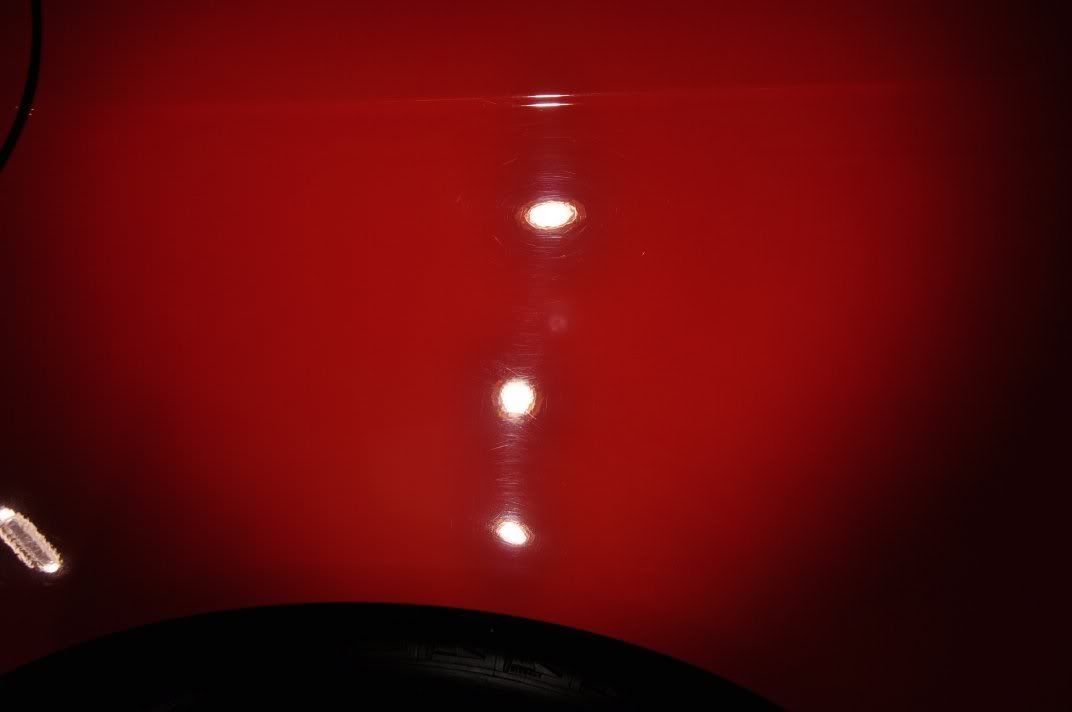

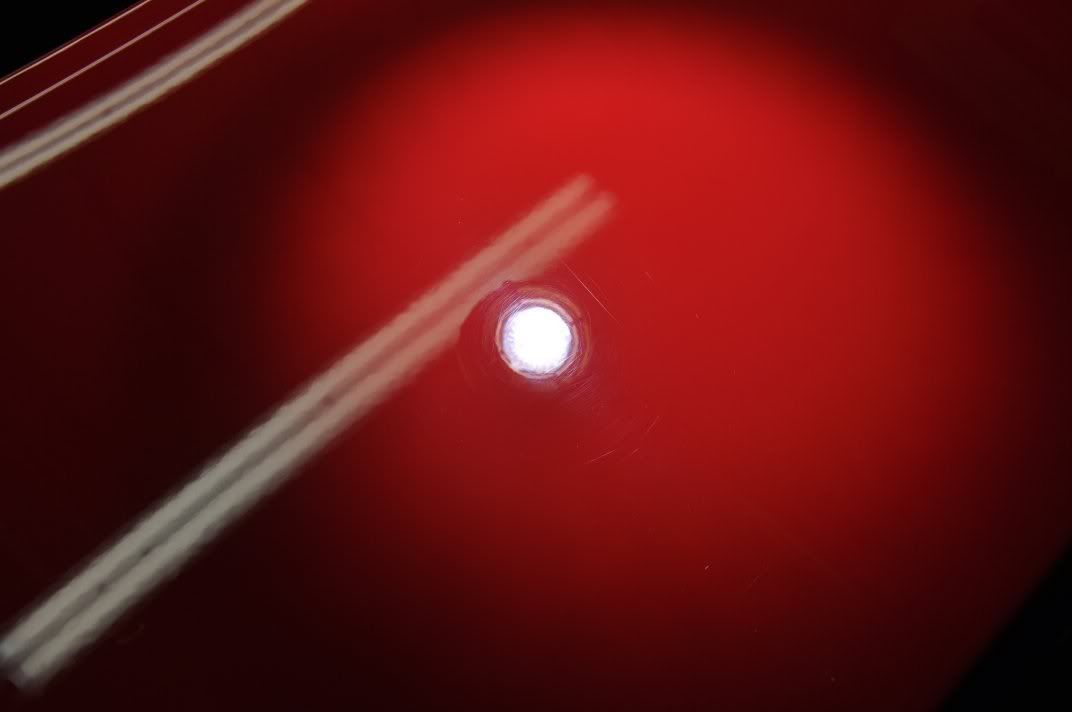

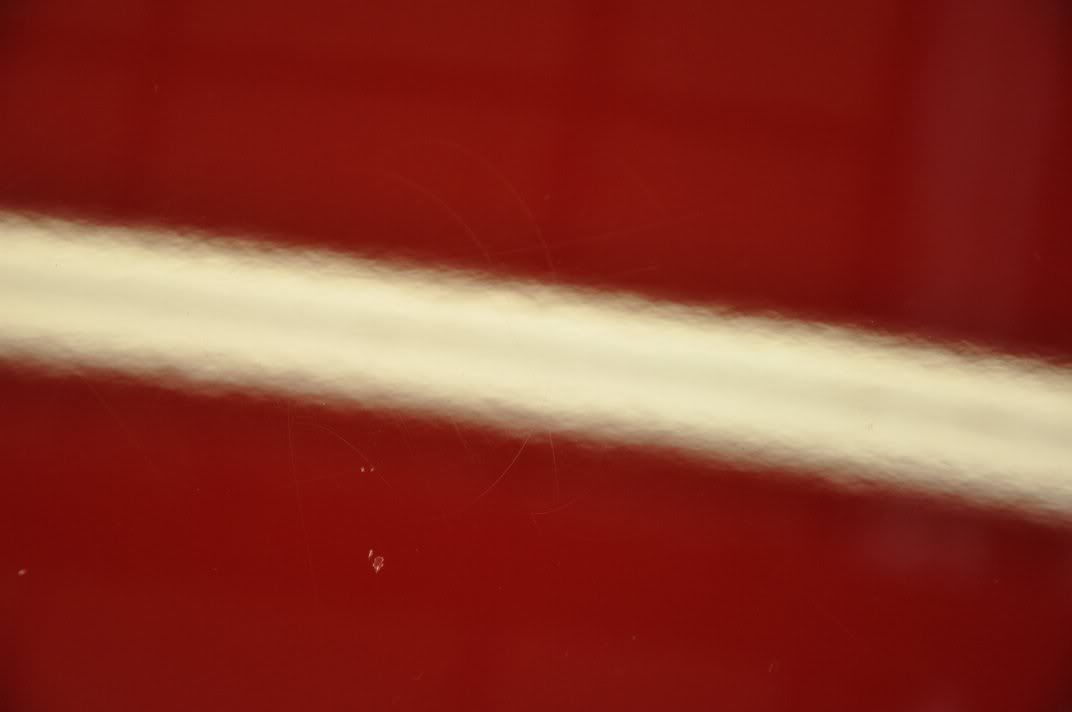

Returning to the detail ... After claying the paintwork was assessed for defects. General medium to in places severe swirls were apparent...

... After claying the paintwork was assessed for defects. General medium to in places severe swirls were apparent...

As always, we start with light abrasive combinations and work up until the desired level of correction is achieved carefully monitoring the paint removal rates to ensure the machining is safe and in the interests of the long term life of the paint.

For the majority of the car, we found Menzerna PO85RD3.02 Intensive Polish sufficed for correction, either using a 3M yellow polishing pad or where required stepping up to a Chemical Guys Hexlogic Green Heavy Polishing pad for a little extra bite. Both standard Zenith point method...

and a regenerating technique...

were used depending on level of cut required.

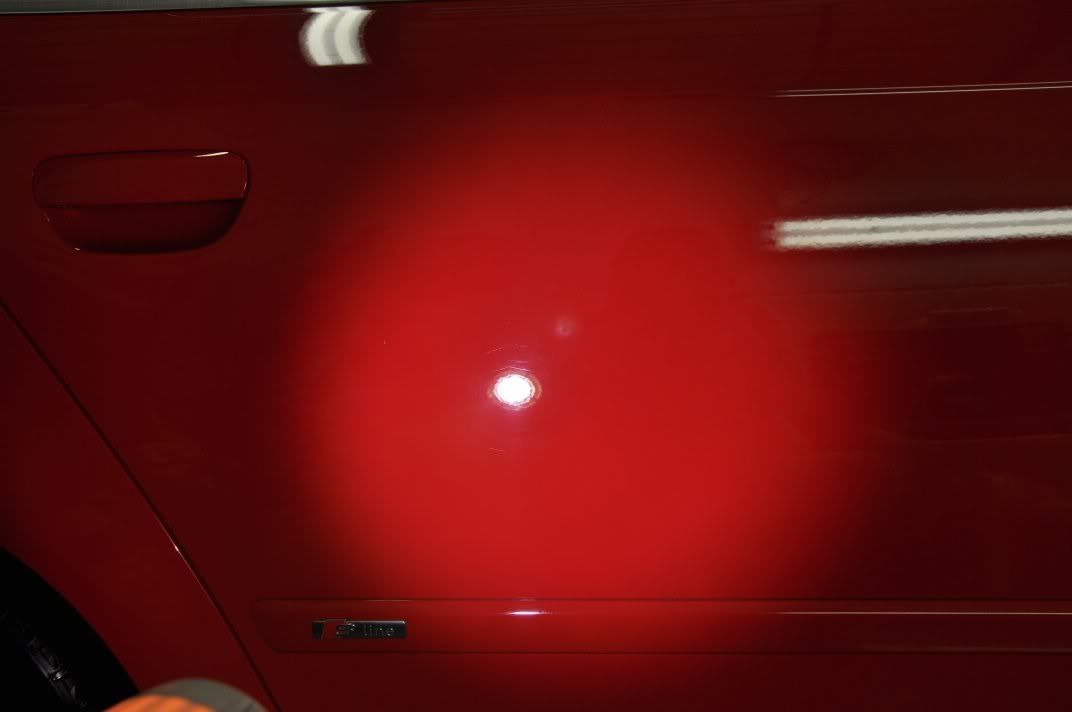

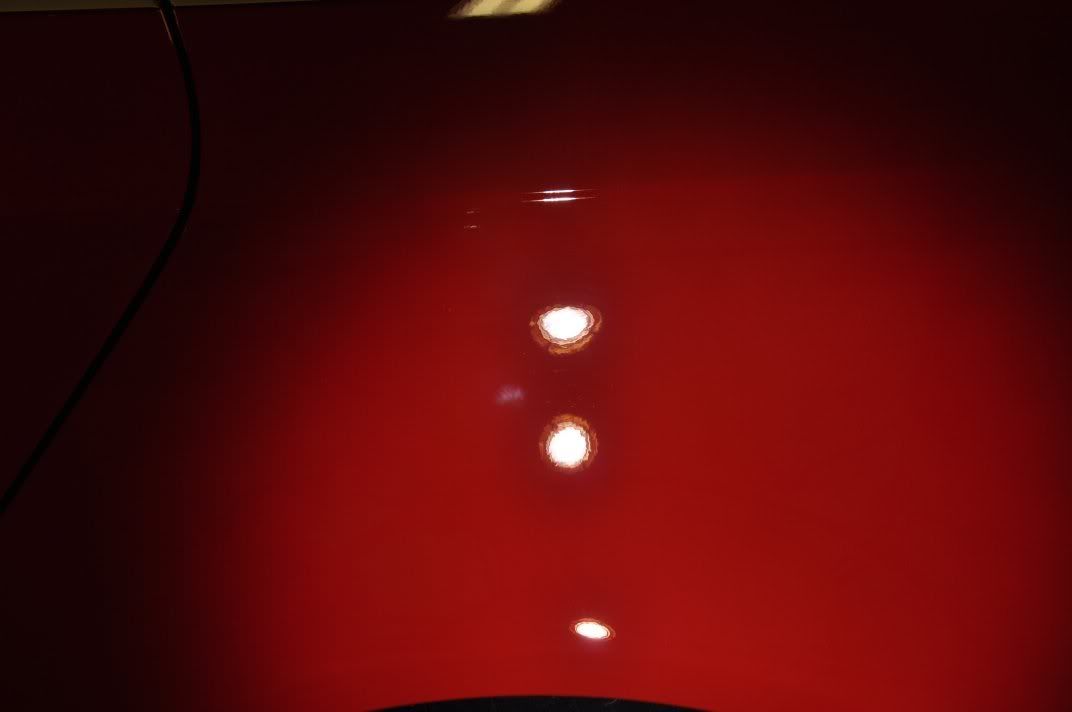

On the bonnet there were more visible RDS...

Here, 3M Fast Cut was used on a Chemical Guys Yellow Hexlogic Compounding Pad to remove the deeper marks...

All paintwork was then refined using Menzerna PO85RD Final Finish with a 3M blue finishing pad (just a little change from my traditional #205, incase I was getting predictable :p).

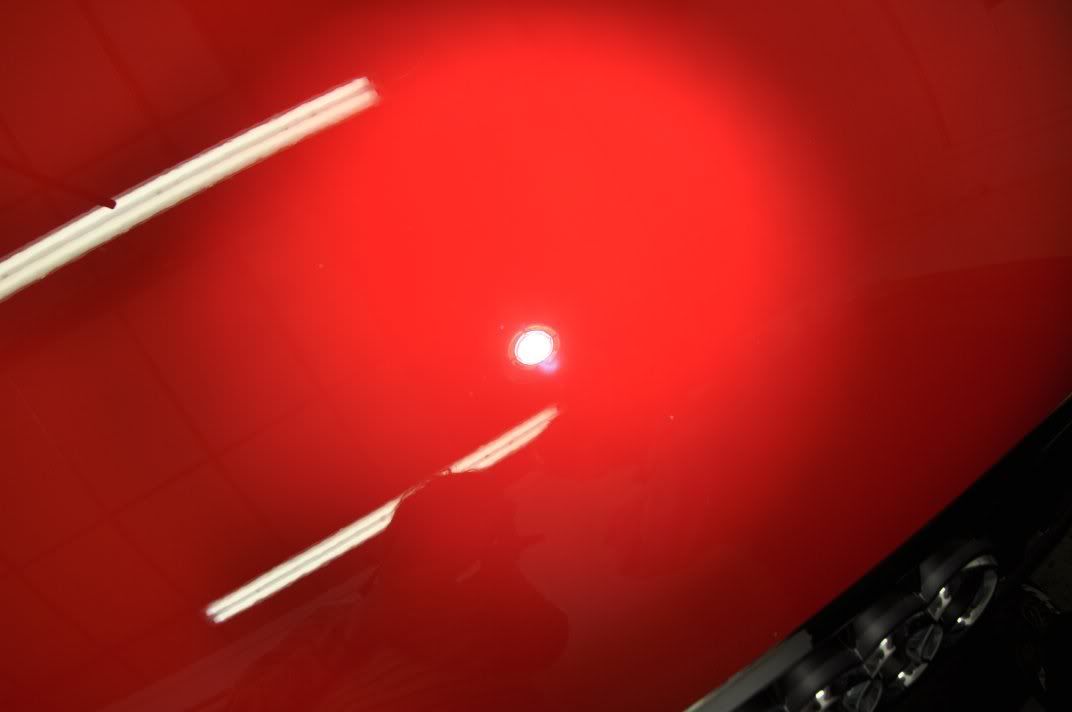

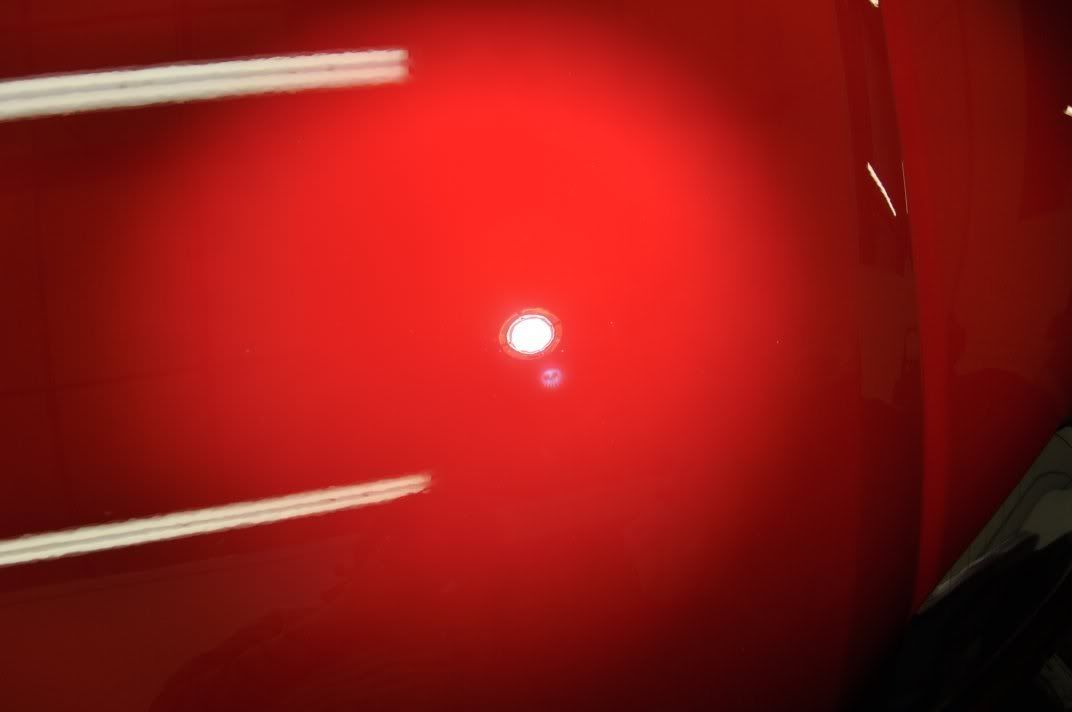

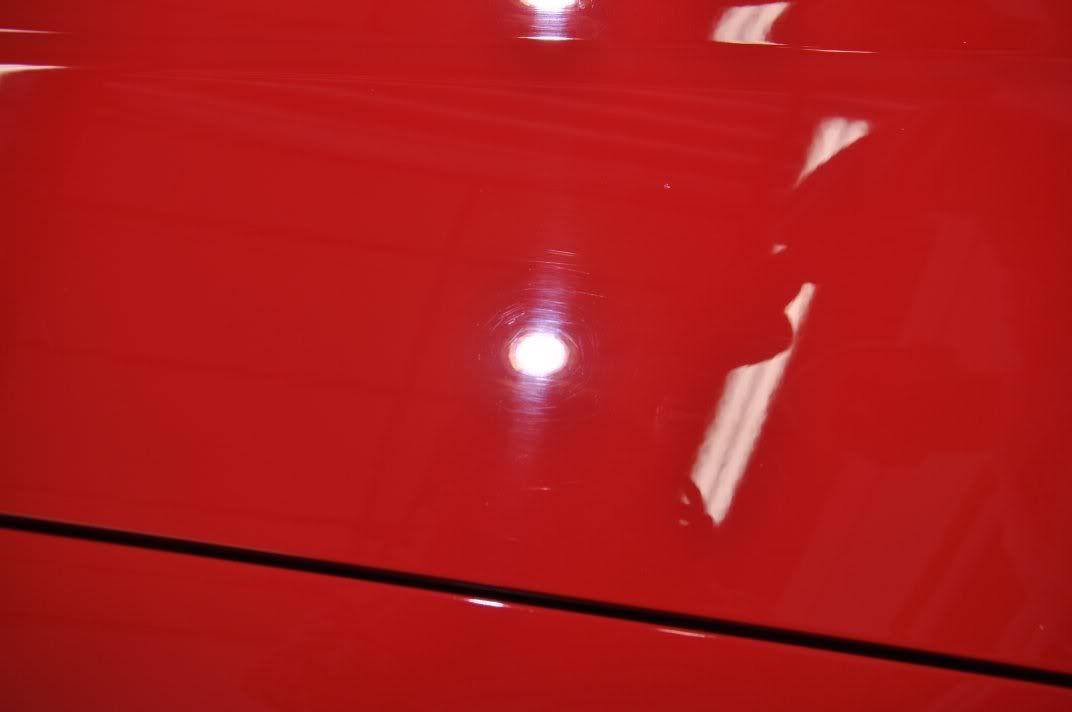

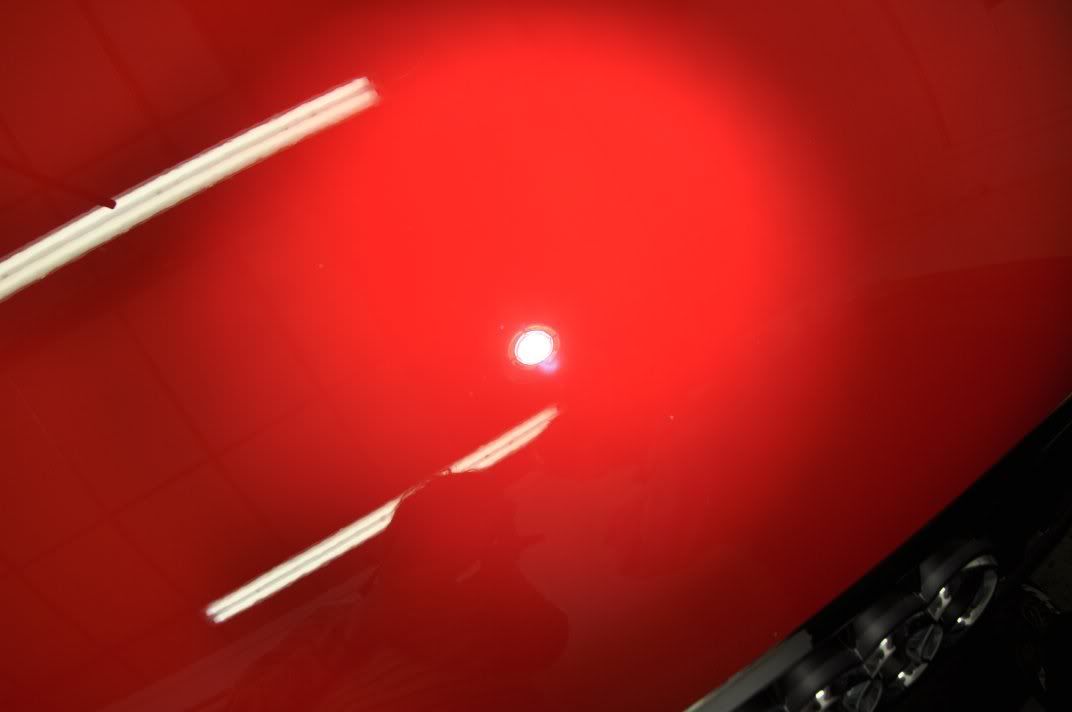

The end results, starting with the bonnet which was mine for the day! :lol::

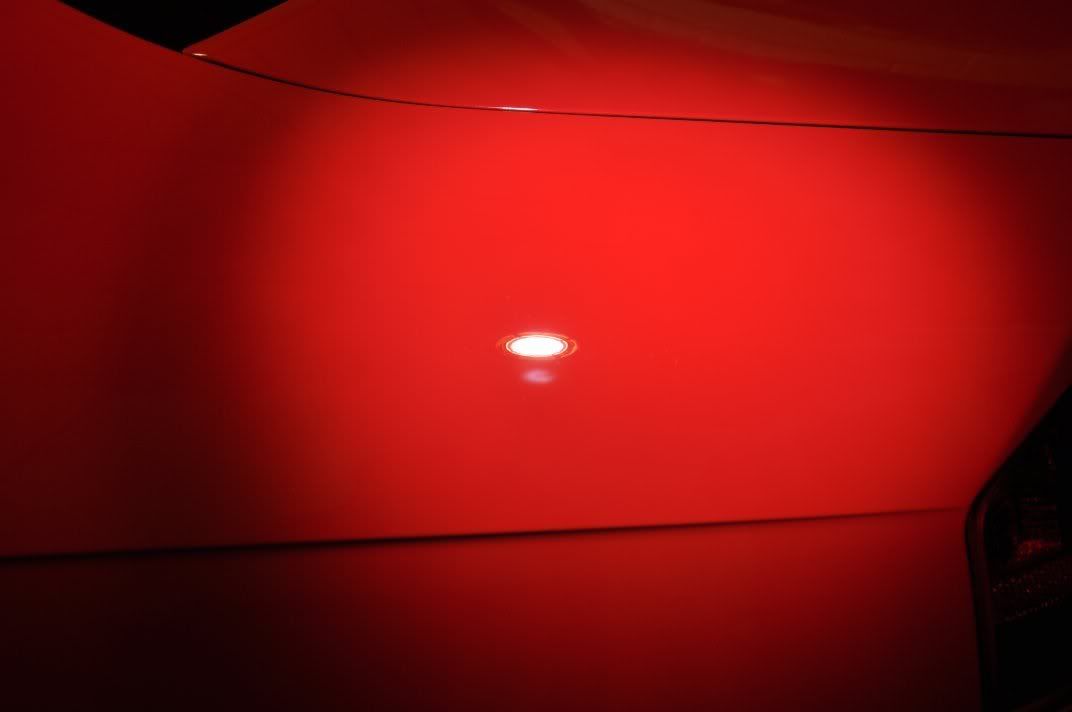

I love solid colours for showing the machine finish - so rewarding to see the Sun Gun nice and sharp

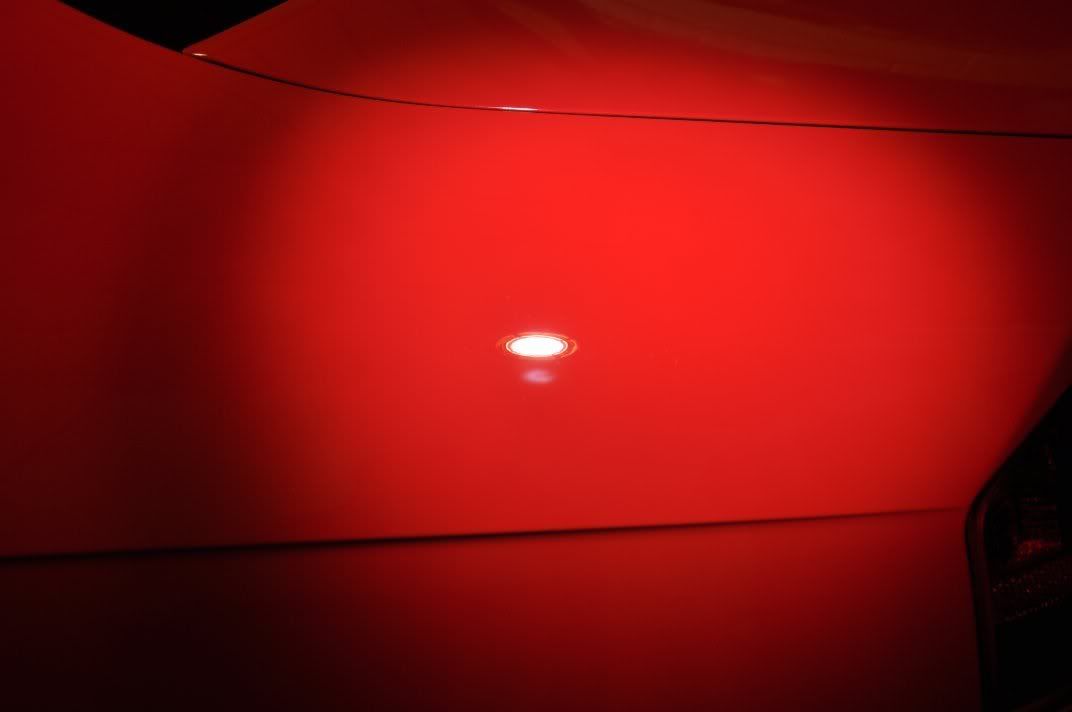

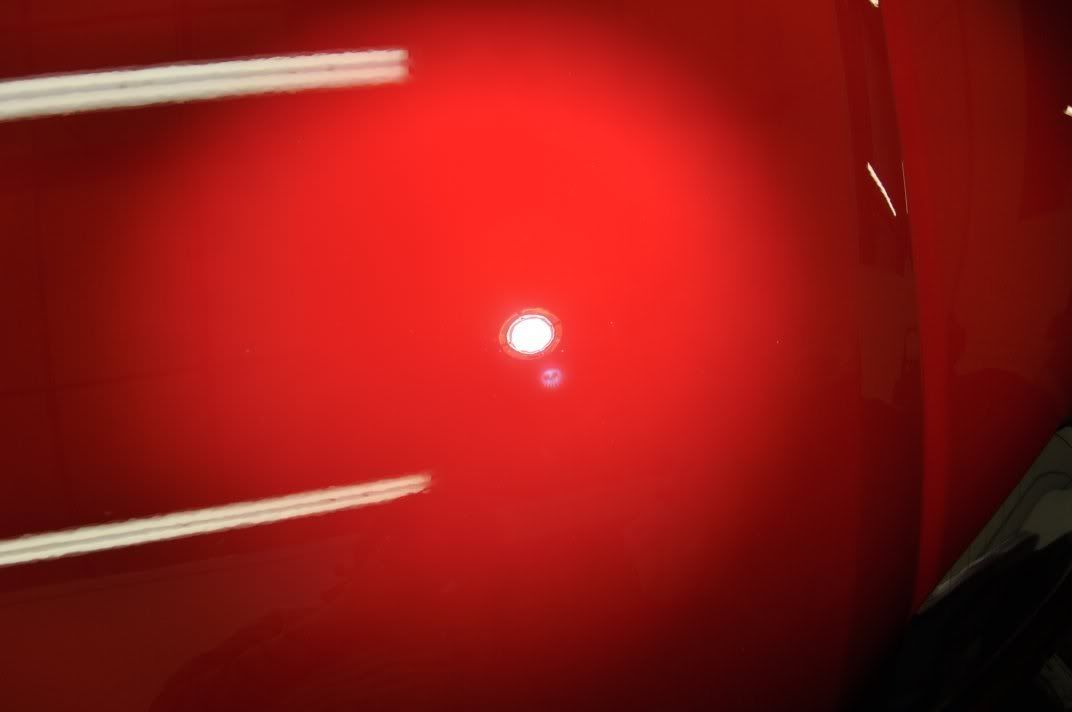

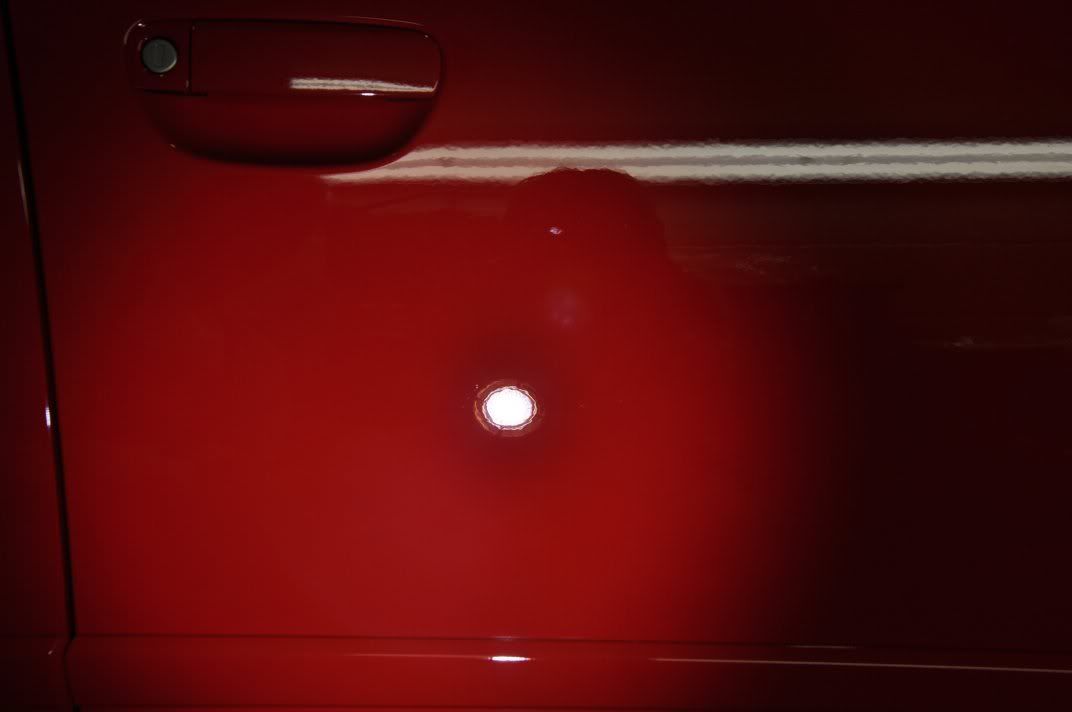

Onto the passenger side, where Stuart must take credit for the refining stage as he took to the rotary very well on the day!:

Gordon was working alongside Stuart on the rear 3/4, team working and sharing hints and tips as they went along...

Bootlid...

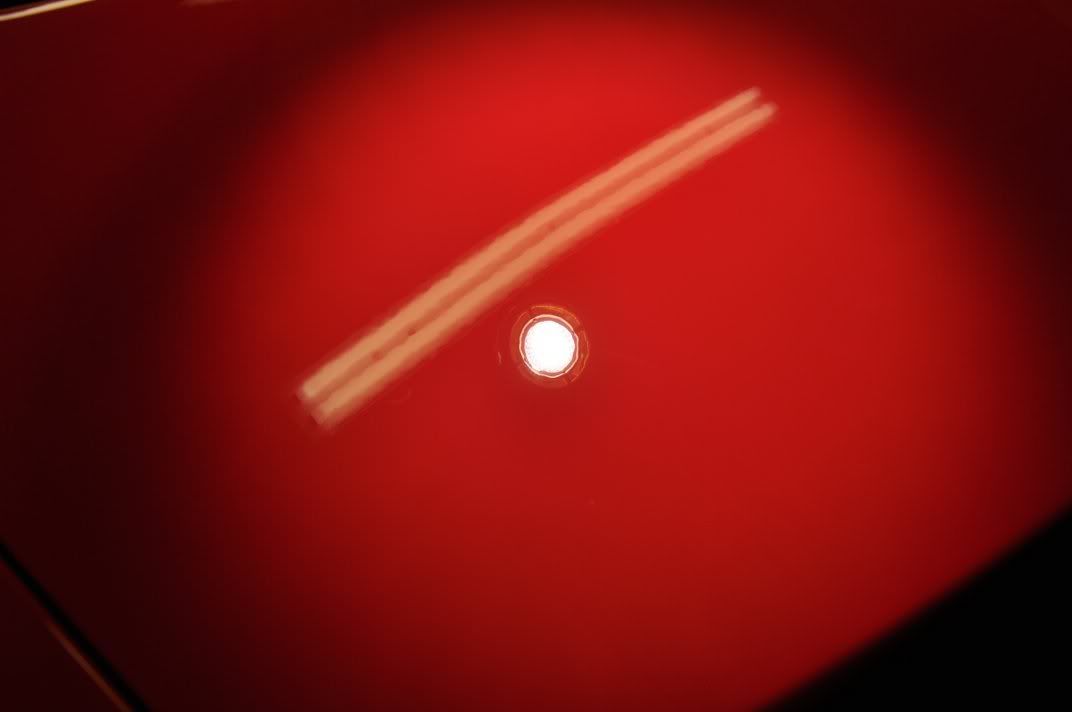

Davy and myself spending time on the driver's side...

Stuart was not just involved in the refining process, but was also working on the correction too as anyone who comes along for a tuition detail would be - you get stuck into the detail with us!

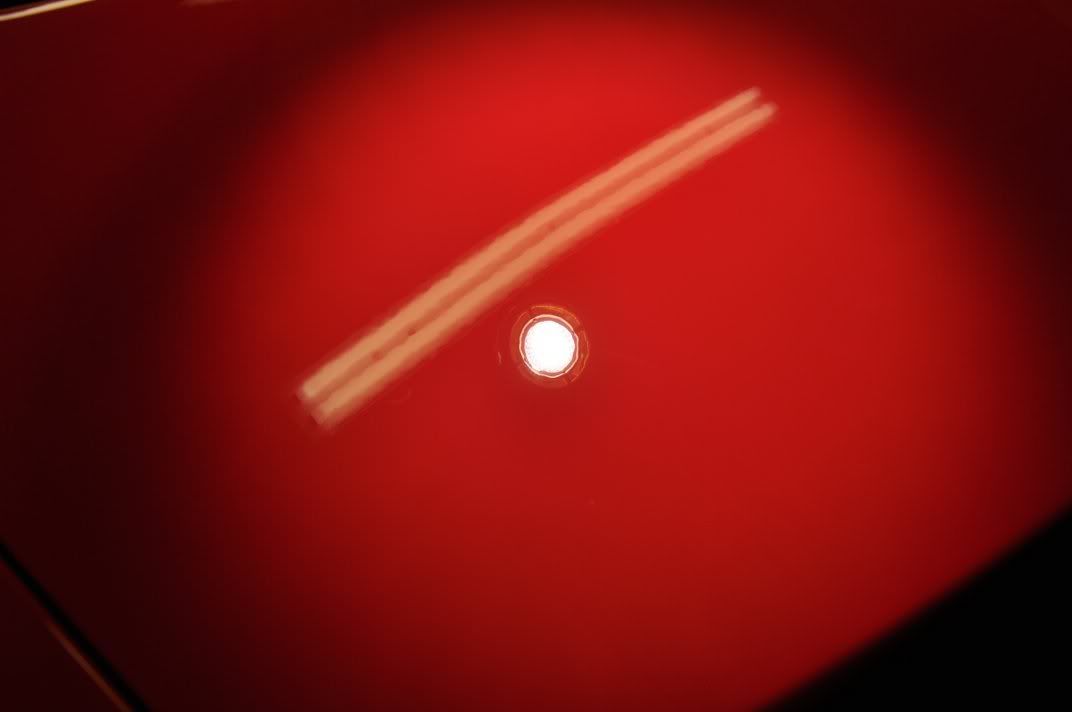

Some from my efforts on driver's door...

And wing...

Cant forget the mirrors...

Today's LSP of choice was Collinite 476S - chosen for its durability to protect the finish we had spent many hours achieving. Still the most durable wax in my experience (hybrid, sealant, whatever you want to call it - it works, and does so damn well!).

Tyres dressed with Espuma RD50, trim with Chemical Guys New Look, glass with Duragloss 751, wheels with FK1000P, aluminium trim with Jeffs Prime, arches dressed with All Seasons Dressing.

To get some full car after shots, and to help show off Davy's sterling work on the roof (:p), I risked life and limb and crawled up onto the unit office roof with the aid of Davy throwing me! Pics from above :

:

Wing in the halide lights...

The roof for Davy:

Some whole car afters from up high:

And back down to earth for our traditional after shots (roll on the summer when its dry and bright outside for our afters! ):

):

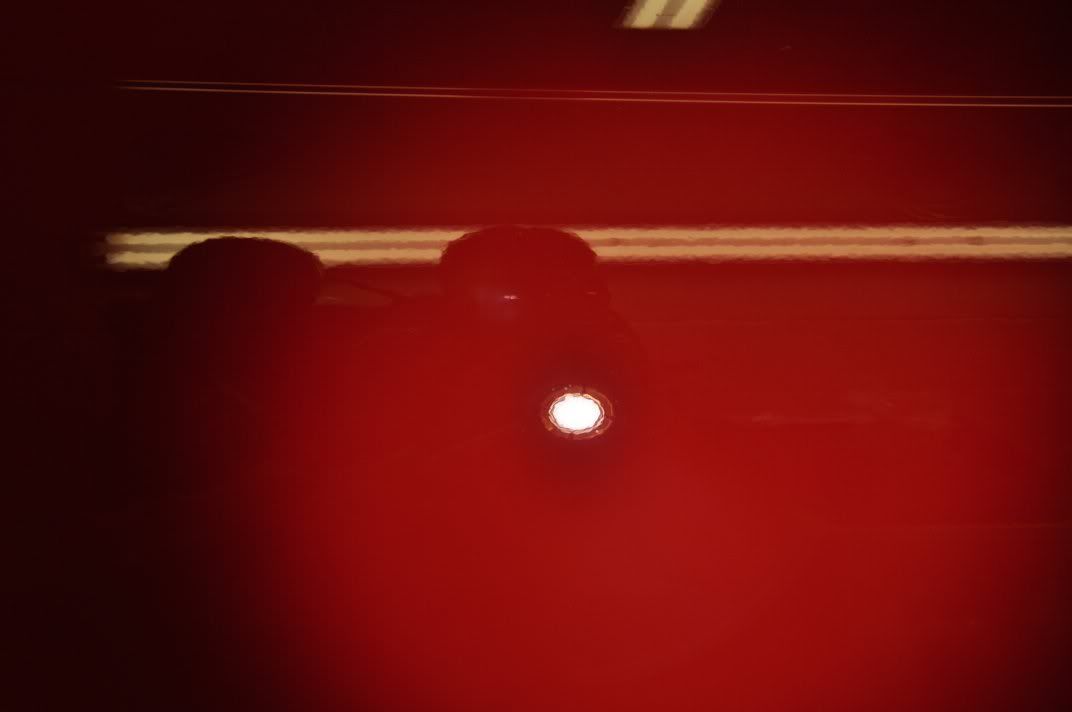

and some reflection-style arty pics...

And finally, some good old Collinite beading:

Davy, Gordon and myself on the team today

Davy, Gordon and myself on the team today

As mentioned in a previous thread, as a team we are looking at pushing forward and expanding our washing techniques to suit different situations where we may be working - from unit where we can use snowfoam and water happily, to showgrounds where washing is restricted with no hose, to inside garages where classic cars cannot be easily moved outside for washing. On this detail, we chose to wash the car inside using Optimum No Rinse shampoo for the bodywork and the steam cleaner for wheels and arches.

ONR for me has major advantages for those wanting to wash their car and make sure its perfect at a show... its not always possible to get a rinsing hose, but getting a bucket of water is much easier. Careful wash technique is required but over the past weeks and months we have been developping this and seeing what works best to ensure safe washing. The car, ready for washing indoors:

As a traditional wash, two buckets prepared with water:

In one bucket, Gordon here adds a couple of capfuls of ONR to the wash bucket...

The philosophy behind ONR is a super slick wash solution which encapsulates dirt so it slides off of the paintwork without marring. This does seem to work, as we have been using Gordon's Vectra as a test mule for this since the summer months

But it does require the correct method to be used, adapt a little from traditiona two bucket wash! The key is not to have shed loads of water on the car, all running pff everywhere - squeeze a lot of the water out of the sponge (do not use a mitt):

But it does require the correct method to be used, adapt a little from traditiona two bucket wash! The key is not to have shed loads of water on the car, all running pff everywhere - squeeze a lot of the water out of the sponge (do not use a mitt):

Then gently with no pressure wipe the sponge over the region of paint. Only go small distances, espeically on dirty panels and return to rinse bucket often to clean sponge and then renew with ONR solution from wash bucket. Some common sense is required here - if the panel is very dirty, go only a very small distance and return to bucket often. Dont press down, keep returning to same area with more passes instead if more cleaning is needed. The sponge should be lightly swept acorss the paint...

The water from the solution then sheets and runs off...

Lightly dry the panel following with a drying towel - as the name suggests, no rinsing is required. This minimises water used, and also minimised water spilling everywhere which when inside or at a showground is highly desireable!

The wheel were cleaned using the Steam Cleaner... as you can see, pretty clean anyway in the befores:

Because they were in good condition, the wheels could be cleaned with no chemicals with the steam cleaner... a little Bilberry, or APC could be added to the cleaning brush. To ensure you dont mark the alloy, as you do with paint, only use very light pressure with the brush and go over areas often rather than trying to shift everything in one go. The wheel insides with the steam cleaner...

You can see the dirt being removed with the method...

Working away on the faces of the wheel...

and on the arches...

The end results...

We'd say they were pretty clean

Now, any severe pitting or tar for example would require a tar remover but be aware that old clay can also be used if for some reason aggressive chemicals cannot be used for removing tar... takes longer, and does ruin the clay but the option is there. The key is to be flexible, widen your armoury of techniques to deal with a variety of situations you may be faced with as the more time I spend detailing, the more I see that traditional methods are not always readily applicable and the ability to change and adapt is very important.

Now, any severe pitting or tar for example would require a tar remover but be aware that old clay can also be used if for some reason aggressive chemicals cannot be used for removing tar... takes longer, and does ruin the clay but the option is there. The key is to be flexible, widen your armoury of techniques to deal with a variety of situations you may be faced with as the more time I spend detailing, the more I see that traditional methods are not always readily applicable and the ability to change and adapt is very important.Returning to the detail

... After claying the paintwork was assessed for defects. General medium to in places severe swirls were apparent...

... After claying the paintwork was assessed for defects. General medium to in places severe swirls were apparent...

As always, we start with light abrasive combinations and work up until the desired level of correction is achieved carefully monitoring the paint removal rates to ensure the machining is safe and in the interests of the long term life of the paint.

For the majority of the car, we found Menzerna PO85RD3.02 Intensive Polish sufficed for correction, either using a 3M yellow polishing pad or where required stepping up to a Chemical Guys Hexlogic Green Heavy Polishing pad for a little extra bite. Both standard Zenith point method...

- Spread at 600rpm

- Begin working at 1200rpm

- Work at 1800rpm until residue clear

- Refine at 1200rpm

and a regenerating technique...

- Spread at 600rpm

- Begin working at 1200rpm

- Work at 1800rpm until residue clear

- Reduce to 1200rpm, no pressure to bring back polish residue

- Work at 1800rpm until residue clear

- Repeat until residue remains clear at 1200rpm

- Refine at 900rpm

were used depending on level of cut required.

On the bonnet there were more visible RDS...

Here, 3M Fast Cut was used on a Chemical Guys Yellow Hexlogic Compounding Pad to remove the deeper marks...

- Spread at 600rpm

- Begin working at 1200rpm

- Work at 2000rpm, firm pressure and moderate machine speeds until defects removed

All paintwork was then refined using Menzerna PO85RD Final Finish with a 3M blue finishing pad (just a little change from my traditional #205, incase I was getting predictable :p).

The end results, starting with the bonnet which was mine for the day! :lol::

I love solid colours for showing the machine finish - so rewarding to see the Sun Gun nice and sharp

Onto the passenger side, where Stuart must take credit for the refining stage as he took to the rotary very well on the day!:

Gordon was working alongside Stuart on the rear 3/4, team working and sharing hints and tips as they went along...

Bootlid...

Davy and myself spending time on the driver's side...

Stuart was not just involved in the refining process, but was also working on the correction too as anyone who comes along for a tuition detail would be - you get stuck into the detail with us!

Some from my efforts on driver's door...

And wing...

Cant forget the mirrors...

Today's LSP of choice was Collinite 476S - chosen for its durability to protect the finish we had spent many hours achieving. Still the most durable wax in my experience (hybrid, sealant, whatever you want to call it - it works, and does so damn well!).

Tyres dressed with Espuma RD50, trim with Chemical Guys New Look, glass with Duragloss 751, wheels with FK1000P, aluminium trim with Jeffs Prime, arches dressed with All Seasons Dressing.

To get some full car after shots, and to help show off Davy's sterling work on the roof (:p), I risked life and limb and crawled up onto the unit office roof with the aid of Davy throwing me! Pics from above

:

:

Wing in the halide lights...

The roof for Davy:

Some whole car afters from up high:

And back down to earth for our traditional after shots (roll on the summer when its dry and bright outside for our afters!

):

):

and some reflection-style arty pics...

And finally, some good old Collinite beading:

Comment